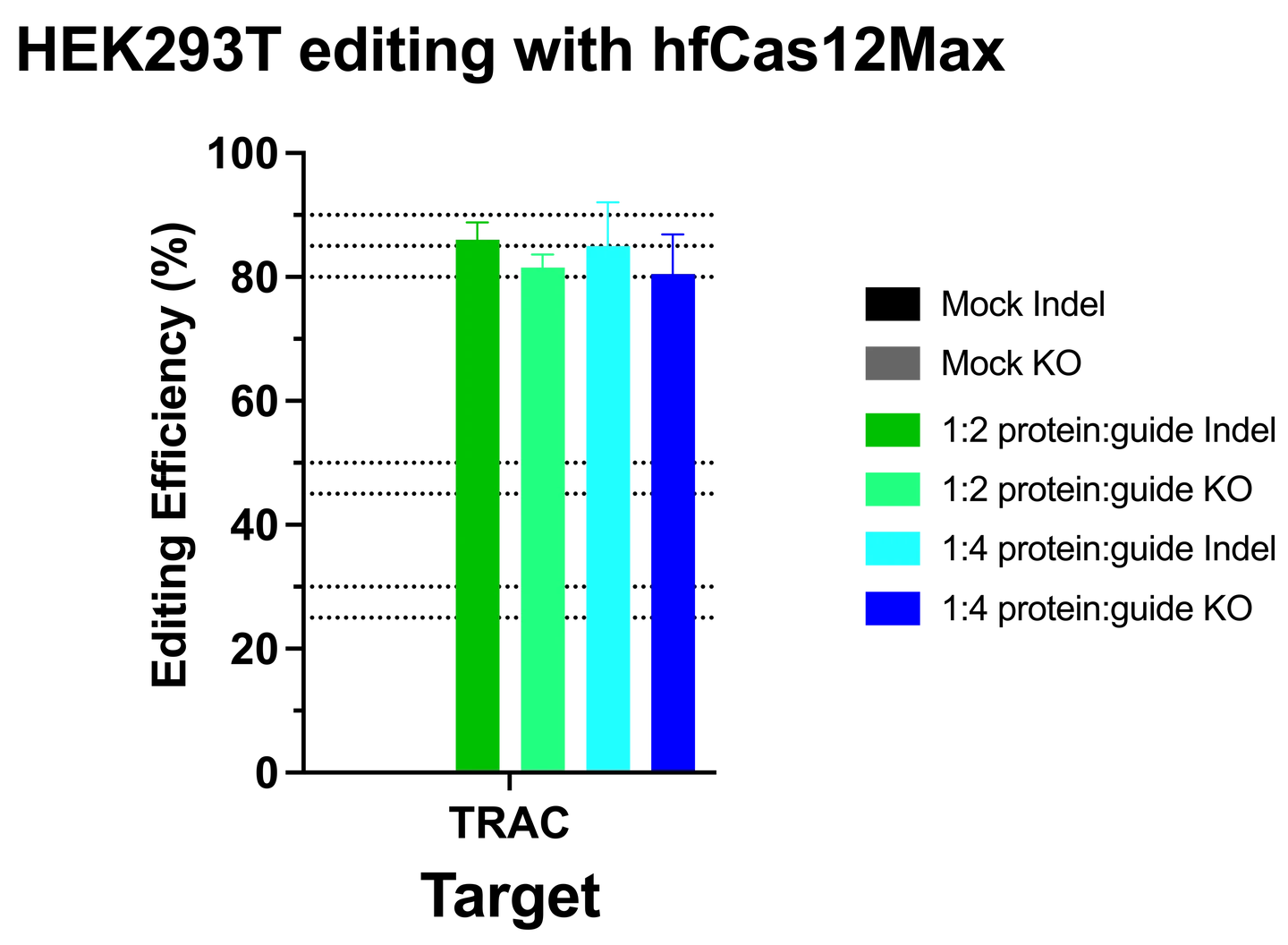

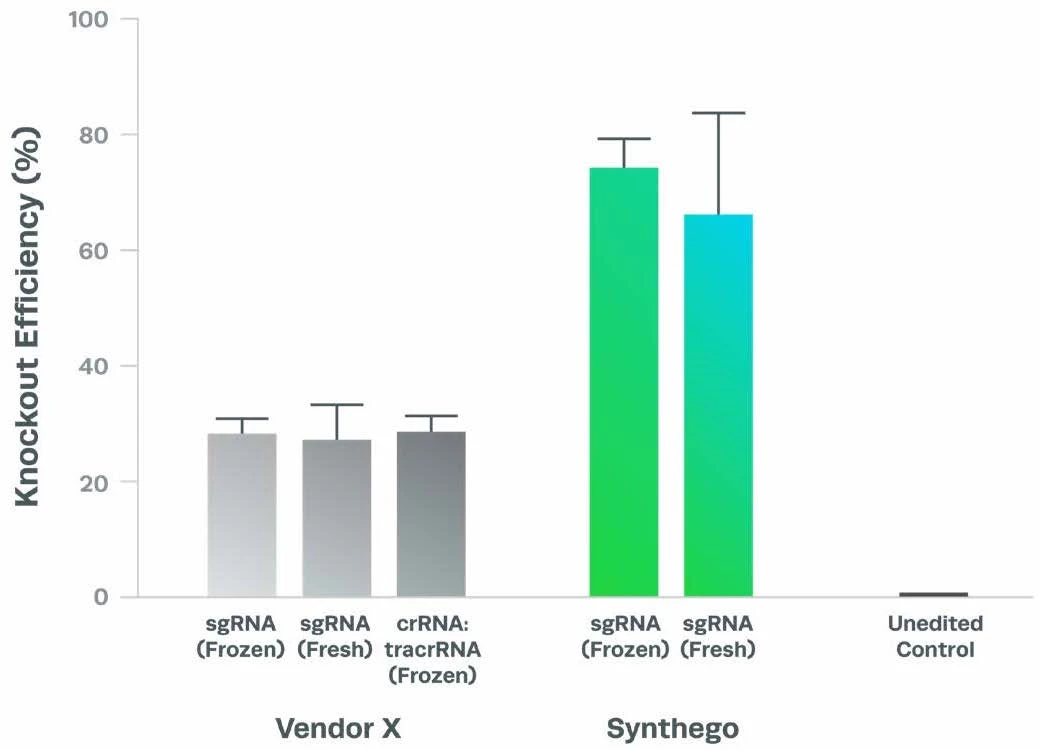

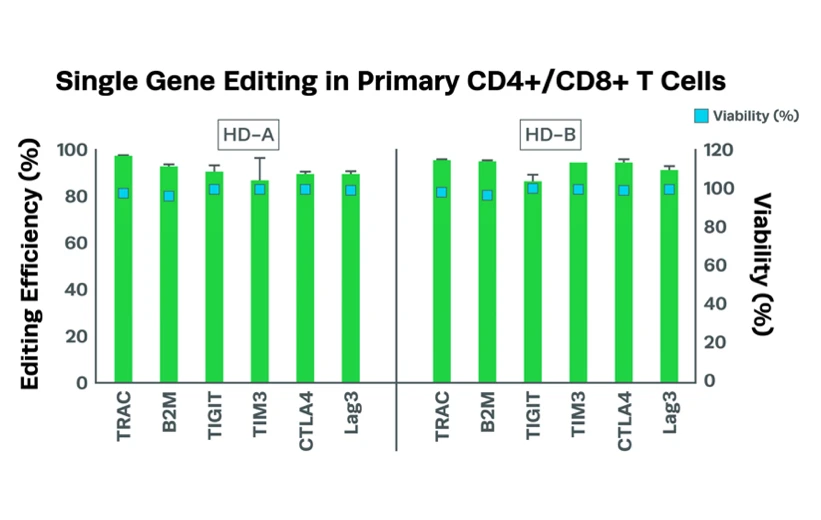

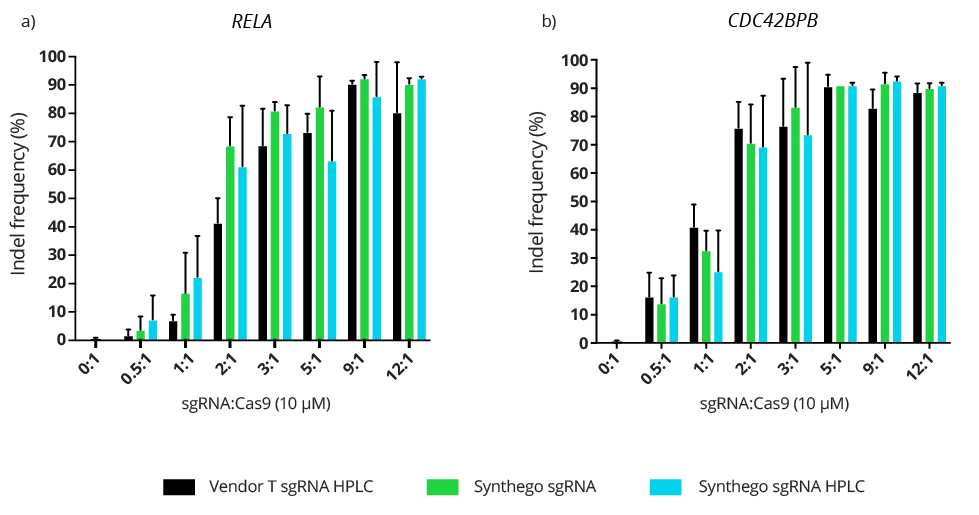

Complexing hfCas12Max nuclease with our best-in-class Research sgRNA achieves consistently high editing efficiencies. If you are seeking alternatives CRISPR gene editing methods, hfCas12Max is the nuclease you need for your next CRISPR experiment or therapeutic development.

Learn more

Webcast featuring eSpOT-ON

Explore More

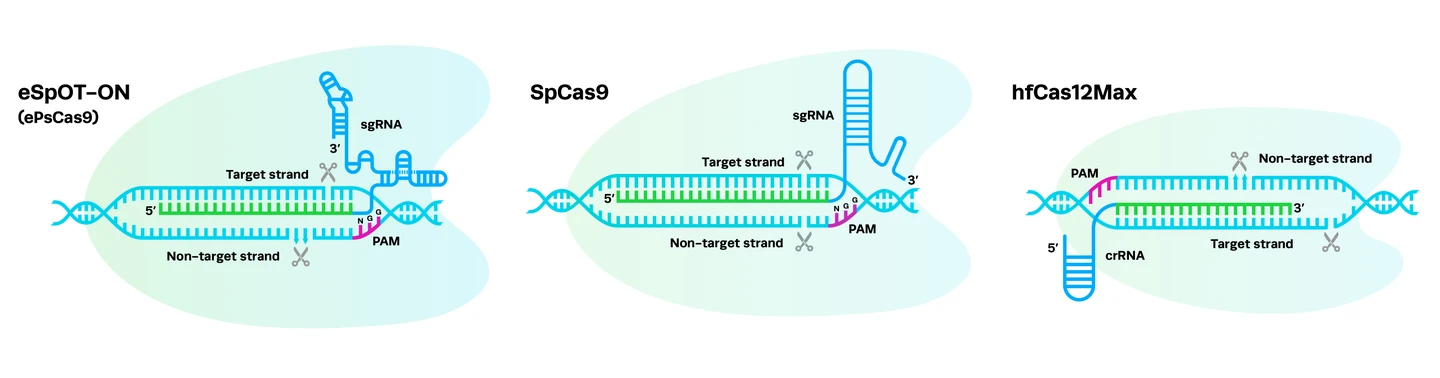

eSpOT-ON Nuclease Protein Available Now

Explore More

Order eSpOT-ON Nuclease mRNA Now